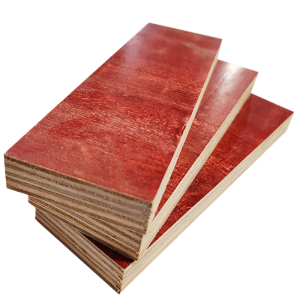

Waterproof Board

Product Details

In addition to PVC, its raw materials include calcium carbonate,stabilizer and other chemicals. In order to produce a better waterproof board, our company draws into a full set of advanced automation, high-capacity production equipment and technology in terms of production technology. We continue to innovate, use high-quality core and surface materials, and hope to provide customers at home and abroad with new and environmentally friendly products. As long as you have requirements, black, white, green or other colors are as you choose.

Property

The properties of the waterproof board are high strength, extremely high UV resistance, extremely high temperature resistance ( up to 230 ℃, its maintaining structural integrity and original physical properties under high temperature), and long-term good planar drainage and vertical water permeability, creep resistance, corrosion resistance of common chemical substances in soil and corrosion resistance of diesel, gasoline and have good ductility.

Characteristics

1. Excellent flexibility, elongation, impermeability and wear resistance.

2. It has good isolation and puncture resistance, acid and alkali resistance and a variety of chemical substances, also has a good dimensional stability.

3. Waterproof board has a wide range of uses, outdoor applications such as anti-seepage of dams, channels, reservoirs, etc., anti-seepage lining of subways, basements and tunnels, anti-seepage of road and railway foundations seepage, indoor applications such as kitchen and bathroom cabinets, door panels, covering board, building and interior decoration, etc.

Specification

| After-sale Service | Online Technical Support |

| Usage | Outdoor/Indoor |

| Place of Origin | Guangxi, China |

| Brand Name | Monster |

| General Size | 1220*2440mm or 1220*5800mm |

| Thickness | 5mm to 60mm or as required |

| Main Material | PVC/ calcium carbonate/ stabilizer /other chemicals,etc |

| Grade | FIRST-CLASS |

| Glue | E0/E1/Water poof |

| Moisture Content | 8%--14% |

| Density | 550-580kg/cbm |

| Certification | ISO, FSC or as required |

| Payment Term | T/T or L/C |

| Delivery Time | Within 15 days upon down payment or upon opening of L/C |

| Min Order | 1*20'GP |

Company

Our Xinbailin trading company mainly acts as an agent for the building plywood directly sold by Monster wood factory. Our plywood are used for house construction, bridge beams, road construction, big concrete projects, etc.

Our products are exported to Japan, UK, Vietnam,Thailand,etc.

There are more than 2,000 construction purchasers in cooperation with Monster Wood industry. At present, the company is striving to expand its scale, focusing on brand development, and creating a good cooperation environment.

Guaranteed Quality

1.Certification: CE, FSC, ISO, etc.

2. It is made of materials with a thickness of 1.0-2.2mm, which is 30%-50% more durable than the plywood on the market.

3. The core board is made of environmentally friendly materials, uniform material, and the plywood does not bonding gap or warpage.

FQA

Q: What are your advantages?

A: 1) Our factories have more than 20 years experiences of producing film faced plywood, laminates, shuttering plywood,melamine plywood,particle board,wood veneer,MDF board,etc.

2) Our products with high-quality raw materials and quality assurance, we are factory-directly sale.

3) We can produce 20000 CBM per month, so your order will be delivered in a short time.

Q: Could you print the company name and logo on the plywood or packages?

A: Yes, we can print your own logo on plywood and packages.

Q: Why we choose Film Faced Plywood?

A: Film Faced Plywood is better than iron mould and can satisfy the requirements of constructing mould, the iron ones are easy to be deformed and can hardly recover its smoothness even after repairing.

Q: What is the lowest priced film faced plywood?

A: Finger joint core plywood is cheapest in price. Its core is made from recycled plywood so it has low price. Finger joint core plywood can only be used two times in formwork. The difference is that our products are made of high-quality eucalyptus/pine cores, which can increase the reused times by more than 10 times.

Q: Why choose eucalyptus/pine for the material?

A: Eucalyptus wood is denser, harder, and flexible. Pine wood has good stability and ability to withstand lateral pressure.